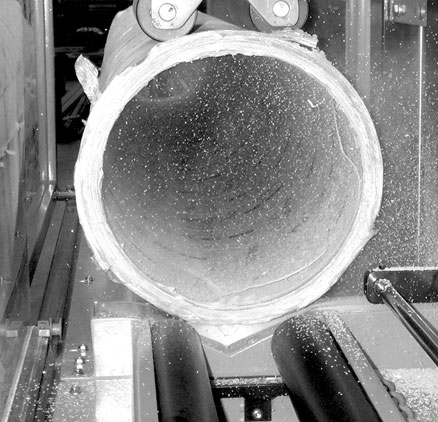

Cardboard core cutting machine

Core cutters can be manual or automatic

Core cutting machines are designed to cut cardboard tubes into different lengths. The cardboard core cutter uses high precision circular blades, which guarantee a clean and precise cut, reducing waste to a minimum.

Manual core cutters

They require the direct intervention of the operator, who positions the cardboard tube and manually operates the machine to carry out the cut. They are generally used for small productions or where flexibility is essential.

Automatic core cutters

These are machines integrated into larger production lines and are able to cut a large number of cores without continuous operator intervention. They can be programmed to cut tubes of various lengths and diameters.

Semi-automatic core cutters

These machines combine elements of both manual and automatic core cutters. The operator can manually load the tube, but the cutting is automatic.

Core cutters can be used in paper mills, to cut cardboard tubes used as a support for paper rolls, in the textile industry, to cut tubes on which fabrics, yarns or tapes are wound, in packaging and plastic film production, to cut cores on which plastic materials or films are wound. Core cutters are essential to ensure efficiency and precision in production operations, reducing downtime and increasing productivity.